This Medium-Duty-Track-Product-Specifications details that it was developed and designed specifically for theatre use as it is not only heavy duty and extremely quiet, but the track will last a lifetime of any building, with minimal maintenance. Our tracks are sold to most markets throughout the world, including America, Asia and Europe. Applications for this system are only limited by imagination, as it is adaptable for room dividers, convention centres, studios, performing spaces and many other similar spaces. The track system operation can be Hand Drawn, Cord Drawn or Motorised. The motor system can be optioned in many different ways pending on speed, load capacities, drift or travel and number of required stops/positions needed.

Short-form

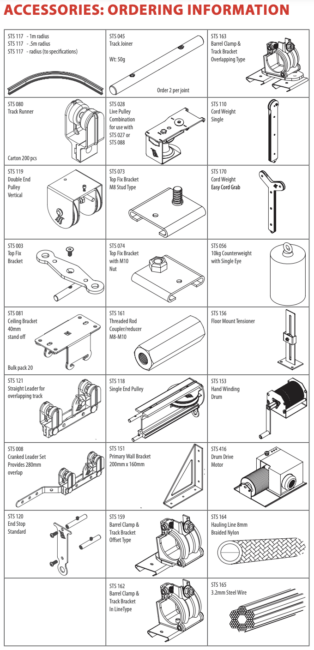

To be Specialty Theatre’s STS117 Medium Duty Track it will be a heavy-duty extruded aluminum section that is anodized in a matte black finish. It is available in lengths up to 5.8 meters. The system is designed to span up to 2.5 meters without the need for intermediate support and can be easily curved to accommodate custom applications. Complementary components such as runners, end pulleys, cranked and straight leaders, joining plates, and mounting brackets are also available. The runners feature black nylon tires with ball bearing wheels, ensuring silent operation. The tracking system, along with all other components, is part of Specialty Theatres’ professional heavy-duty tracking system.

Long-form

Product:

- Product Name: STS117 Medium Duty Track

- Manufacturer: Specialty Theatre

- Page Title: Medium Duty Track Product Specifications

Features:

- Robust

- Extremely quiet

- Black anodised finished

- Durable

- Last a lifetime of the building

- Requires minimal maintenance

Overall Specifications:

STS Track Proprietary Line – Available in 5800 length without joins in Black anodised finish. Track can span to 2500mm between supports. Curves are to be 1000mm unless otherwise stated. Track runners are to be provided at 250mm centres for curtains up to 3000mm wide, and 300mm centres for curtains over 3000mm wide.

- Material: Aluminium

- Weight: 1.75kg per 1000mm

- Standard Length: 5800mm

- Finish: Black Anodised Matt

- Suspension: Up to 2500mm between centres

- Standard bends: 500/750/1000/1200mm

- Fixing: Top, face, barrel & beam fixing brackets available

- Standard Radius: 90 – 45

Technical Specifications:

- The tracking system shall consist of a heavy duty extruded aluminium section that is anodised matt black, available in lengths up to 5.8 meters.

- The tracking system shall be capable of spanning up to 2.5m without intermediate support and shall be able to be readily curved to suit custom applications.

- Components to suit and complimenting the track shall be available as well, including runners, end pulleys, cranked and straight leaders, joining plates, mounting brackets, etc.

- The runners will feature black nylon tyres with ball bearing wheels that will be silent during operation.

- The tracking system and all other components shall be Specialty Theatres’ professional heavy duty tracking system and components.

Performance:

- Load Capacity: Several hundred to several thousand pounds often fall within the range of the mild loads that medium-duty tracks are designed to carry. They are capable of supporting drapes, screens, and other light- to medium-weight components used in performances, exhibits, or events.

- Smooth Movement: Movement along medium-duty tracks is smooth and reliable. They are made to ensure simple, dependable opening and closing of drapes or other hung items while minimising friction. Precision placement and flawless transitions are made possible by smooth operation.

- Versatility: Medium-duty tracks can be used in a variety of locations, such as theatres, conference rooms, trade exhibitions, and more. They offer flexibility for diverse stage designs and configurations since they can handle numerous curtain styles, such as pleated curtains, grommet curtains, or tab-top curtains.

- Durability: The construction of medium duty tracks uses strong materials like steel or aluminium to ensure lifespan and resilience to wear and tear. They can survive constant use and the requirements of a theatrical or event setting without losing quality.

- Noise reduction: Many medium-duty tracks are built with noise-canceling components such as nylon wheels or ball bearings to reduce noise during operation. This is crucial in environments like theatres where it’s preferred to walk quietly to prevent interruptions during performances.

- Adaptability: Medium duty rails are frequently made to work with common rigging systems. They are simple to implement into a theatre or event venue because they may interact with already-existing infrastructure like fly systems or grid systems.

- Safety: Safety is a top priority for medium-duty tracks, which have safe locking mechanisms to stop drapes or other hung parts from accidentally moving or being knocked loose. They are made to adhere to safety rules and standards, guaranteeing the safety of the cast, crew, and spectators.

Maintenance and Care:

- Regular Inspection: Visually inspect the track system on a regular basis for any indications of wear, damage, or misalignment. Check for any loose or broken parts that could compromise the functioning of the track.

- Cleaning: Prevent the accumulation of dust, grime, and other debris on the track system. To clean the track of any debris or foreign matter, use a soft cloth or brush. Abrasive or harsh chemicals should not be used as they may harm the track surface.

- Lubrication: Follow the manufacturer’s instructions when lubricating the track’s moving components, such as the rollers and bearings. Lubrication promotes smooth functioning by lowering friction.

- Track Alignment: Make sure the track system is straight and level by periodically checking its alignment. Make the required changes to bring the track back into appropriate alignment if any misalignment is found.

- Checks: Regularly check the safety of the complete track system, including the mounting brackets, hardware, and any related rigging apparatus. Keep an eye out for any damage, corrosion, or wear that could jeopardise the track’s performance and safety. Any worn or broken parts should be replaced right away.

- Documentation and Records: Maintain thorough records of all inspections, repairs, and maintenance procedures carried out on the medium-duty track system. This paperwork makes it easier to keep track of maintenance history, spot reoccurring problems, and make sure safety standards are being followed.

Warranty:

- Please refer to the Terms & Conditions page on our website.

Contact Us – Architects & Estimators

Now that you know the Medium Duty Track Product Specifications head over to our Architects & Estimators page and fill out the contact form with the relevant details per the above.

Additional Resources

Theatre and Cinema Resources Page

Other

NOTE: Specifications are subject to change without notice. While all due care and attention have been taken in the preparation of this document, Specialty Theatre Pty Ltd shall not be liable for any inaccuracies or omissions which may occur therein. Manufactured by Specialty Theatre Pty Ltd. ACN 661 878 271.