As described in the Rotary Suspension Product Specifications, The STS010 Rotary Suspension Unit is a unique and world-class system that allows the configuration of the stage leg curtains to any angle. This system gives the versatility and option to change the stage set from theatrical performances to a lecture theatre black box setup quickly and easily.

Short-form

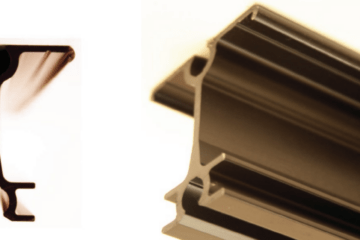

To be Specialty Theatre’s STS010 Rotary Suspension Unit it will be a cutting-edge system that provides exceptional flexibility in configuring stage leg curtains to any desired angle. This unique system enables seamless transitions between theatrical performances and lecture theatre black box setups with ease and efficiency. The key features of this system include its robust and reliable construction, eliminating the need for ladders when adjusting the orientation. It utilizes a single cable locking system, ensuring user-friendly operation. The movement of the system is silent, allowing for smooth and uninterrupted performances. With a working load limit of 150KG, it is designed to handle heavy loads with ease.

Long-form

Product:

- Product Name: STS010 Rotary Suspension Unit

- Manufacturer: Specialty Theatre

- Page Title: Rotary Suspension Product Specifications

Features:

- Robust and reliable

- No need for ladders to change orientation

- Single cable locking system

- User friendly

- Silent movement

- Working load limit of 150KG

Performance:

- Smooth Rotation: A well constructed rotary suspension system should provide smooth and controlled rotation, enabling accurate positioning and movement of suspended elements. Throughout performances, it need to offer dependable rotation that is constant, allowing for smooth transitions and dynamic visual effects.

- Load Capacity: The rotating suspension system should have a load capacity that is specified and fits the needs of the intended use. To ensure the safe and secure suspension of props, scenery, or other elements, it should be able to support a variety of weights frequently seen in theatre productions.

- Control and Rotation Range: The system should offer a predetermined rotation range that enables a variety of movement alternatives. The rotation speed and direction should be adjustable, allowing us a variety of stage design options. The control system must be clear and exact in order to enable precise positioning and coordinated movements.

- Safety and Stability: A high-performing rotary suspension system should place a high priority on safety and stability. It ought to have reliable locking mechanisms to stop inadvertent rotation or movement while it is being used. Without compromising its stability or endangering the safety of performers and crew, the system must be built to endure dynamic loads and outside influences.

- Durability and Reliability: The rotary suspension system’s performance is dependent on its durability and dependability. It ought to be built using sturdy materials and parts that can survive frequent use and the demands of theatrical productions. The system should continue to operate consistently and dependably throughout time by maintaining its performance characteristics.

- Compatibility and integration: The rotational suspension system ought to be created to be compatible with and integrated with common theatrical rigging systems. It should operate effectively both during installation and operation and should smoothly interact with current infrastructure, such as fly systems or grid systems.

Maintenance and Care:

- Regular Inspection: Check the rotating suspension system on a regular basis for any indications of wear, damage, or misalignment. Examine each component for any problems that can impair the system’s functioning, including the rotating mechanism, bearings, cables, and locking mechanisms.

- Lubrication: Use the right lubricant on the bearings and rotating mechanism as directed by the manufacturer. This ensures that the system rotates smoothly and effectively. Refer to the manufacturer’s instructions for information on the necessary lubrication type and frequency.

- Cleaning: Maintain a clean, dust-free environment around the rotational suspension system. Remove any buildup of debris or foreign objects that can obstruct the system’s operation on a regular basis. Avoid using harsh chemicals or abrasive products that could harm the components by carefully cleaning them with a soft cloth or brush instead.

- Usage: Use the rotary suspension system within its designated load capacity to ensure proper usage. The system’s effectiveness and safety may be jeopardised by overloading, which places undue stress on its parts. For weight restrictions and limitations, adhere to the manufacturer’s instructions.

- Safety checks: The complete suspension system, including the attachment points, cables, and locks, should undergo regular safety checks. Keep an eye out for any wear, fraying, or other damage that could jeopardise the integrity of the system. To maintain safety, replace any worn or damaged components right away.

- Professional Maintenance: Take into account arranging for trained rigging experts to do routine professional maintenance. When necessary, they can carry out more thorough examinations, modifications, and repairs. Before they develop into larger issues, professional maintenance can assist in identifying and resolving any possible issues.

- Documentation and Records: Keep thorough records of all rotating suspension system maintenance tasks, inspections, and repairs. This documentation makes it easier to keep track of the system’s history, spot reoccurring problems, and make sure safety requirements are being followed.

Warranty:

- Please refer to the Terms & Conditions page on our website.

Contact Us – Architects & Estimators

Now that you know the Rotary Suspension Product Specifications head over to our Architects & Estimators page and fill out the contact form with the relevant details per the above.

Additional Resources

Theatre and Cinema Resources Page

Other

NOTE: Specifications are subject to change without notice. While all due care and attention have been taken in the preparation of this document, Specialty Theatre Pty Ltd shall not be liable for any inaccuracies or omissions which may occur therein. Manufactured by Specialty Theatre Pty Ltd. ACN 661 878 271.