Per the Curtain Runner Product Specifications, The STS 080 track runner is a sealed ball bearing wheeled runner, manufactured from heavy duty polypropylene. Manufactured in two halves, the two pieces connect readily, but allow for simple removal when required.

The runner allows curtains, scrims and cloths to be suspended from traditional cord or cotton sash ties. The runner is configured to carry 30 kgs and is designed for use with both the STS 075 and STS 117 track.

Available in black or white polypropylene.

Reduced pricing available for runners purchased in bulk.

Short-form

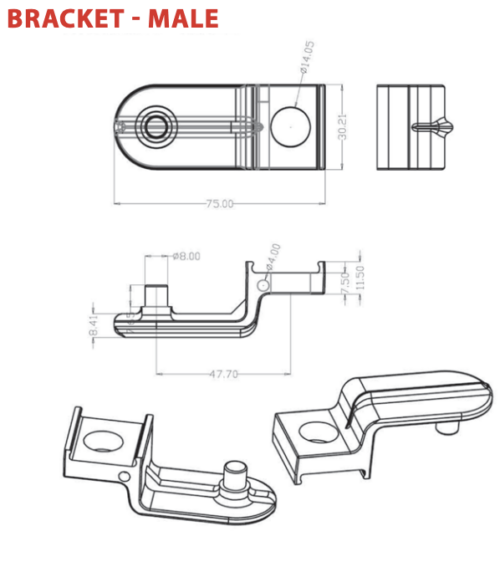

To be Specialty Theatre’s STS080 Performance Space Curtain Runner the assembly will consist of two identical parts made from black reinforced nylon. It features a roller-type bearing and a 19mm diameter wheel. The runner easily snaps together and can be removed from the track as needed. It is specifically designed for compatibility with STS 117 and STS 075 track systems.

Long-form

Product:

- Product Name: STS080 Performance Space Curtain Runner

- Manufacturer: Specialty Theatre

- Page Title: Curtain Runner Product Specifications

Features:

- Sealed ball bearing runner

- Manufactured from heavy duty polypropylene

- Two pieces for easy connection

- Easy removal when required

- Carry up to 30 kgs

- Available in black or white

- Quiet operation

Overall Specifications:

- WLL: 30kgs

- Dimensions: 50mm x 25mm x 20mm

- Colour: Black/White

- Material: Nylon

- Bearing Type: Ball Bearing

Technical Specifications:

- The assembly of this runner is in two identical parts fitting together. They are moulded from black reinforced nylon.

- The bearing is a roller type bearing.

- The wheel is 19mm in diameter.

- The runner snaps together as two identical parts and are removable from the track.

- This runner is suitable for use with the following STS 117 and STS 075

Performance:

- Smooth and Quiet Operation: Curtain runners should move silently and easily down the track, making opening and closing curtains simple. To prevent distracting noises during performances, they should work quietly.

- Load Capacity and Durability: Curtain runners should be strong enough to support the weight of the curtains as well as any other accessories or drapes. To ensure safe and dependable functioning, they should have a designated weight capacity that satisfies the demands of the curtains being used.

- Flexibility and Compatibility: Curtain runners should be flexible and adaptable with a range of curtain styles, including grommet, tab-top, and pleated curtains. They should allow for versatility in terms of modifying the curtains’ width and length to accommodate various stage setups and sizes.

- Smooth Transitions and Accurate Positioning: Curtain runners should enable smooth transitions when raising or lowering curtains without any jerking or uneven movements. They should make it possible to place the curtains precisely where needed, ensuring exact scene transitions and stage setups.

- Easy Setup and Maintenance: Curtain runners should be made to be simple to set up so that setup is rapid and hassle-free. Additionally, they must make it simple to do convenient maintenance, including lubrication or cleaning of the runners with simple access.

- Safety elements: To prevent curtains from accidentally dropping or dislodging, curtain runners should include safety elements. This could involve safe locking devices or safety stops to guarantee that the curtains stay put while performances are taking place.

- Compatibility: Track System Compatibility Curtain runners should work with the regular, standard track systems used in theatres. They ought to be able to move freely along the entire length of the track without any hindrance or resistance.

- Longevity and Reliability: Top-notch curtain runners ought to be made to last, with strong materials and construction that can resist heavy use and the demands of theatre settings. In order to provide dependable and consistent functioning, they should keep their performance characteristics over time.

Maintenance and Care:

- Regular Inspection: Visually inspect the curtain runners on a regular basis to look for signs of wear, damage, or misalignment. Look for any loose or damaged parts that can interfere with the runners’ ability to move smoothly.

- Lubrication: Lubrication ensures friction is reduced and that the track moves smoothly.

- Cleaning: Keep dust, grime, and debris off the curtain runners. Remove any buildup of debris or foreign objects that can obstruct the runners’ effortless motion on a regular basis. Avoid using abrasive cleaners or harsh chemicals on the runners; instead, gently clean them with a soft cloth or brush.

- Track Cleaning: To guarantee peak performance, the track should also be routinely cleaned in addition to the runners. Clear away any trash or other objects that can restrict the runners’ motion. To clean the track, use a moist cloth or a track cleaning device.

- Tighten Loose Components: Regularly inspect the curtain runners for any loose screws or bolts and tighten them as necessary. The performance of the runners might be negatively impacted by loose parts that lead to instability or uneven movement.

- Inspections: Conduct safety inspections on all components of the curtain runner system, such as the track, the brackets, and any additional hardware. Keep an eye out for any damage, corrosion, or wear that could jeopardise the system’s integrity. To ensure safe and dependable functioning, replace any worn or broken components right away.

- Professional Maintenance: Take into account arranging for regular, qualified theatre technicians or rigging specialists to do professional maintenance. When necessary, they can carry out more thorough examinations, modifications, and repairs. Before they develop into larger issues, professional maintenance can assist in identifying and resolving any possible issues.

- Documentation & Records: Keep thorough records of all cleaning, maintenance, and repair work done to the curtain runners. This paperwork makes it easier to keep track of maintenance history, spot reoccurring problems, and make sure safety standards are being followed.

Warranty:

- Please refer to the Terms & Conditions page on our website.

Contact Us – Architects & Estimators

Now that you know the Curtain Runner Product Specifications head over to our Architects & Estimators page and fill out the contact form with the relevant details per the above.

Additional Resources

Theatre and Cinema Resources Page

Other

NOTE: Specifications are subject to change without notice. While all due care and attention have been taken in the preparation of this document, Specialty Theatre Pty Ltd shall not be liable for any inaccuracies or omissions which may occur therein. Manufactured by Specialty Theatre Pty Ltd. ACN 661 878 271.